Have any questions?

+44 1234 567 890

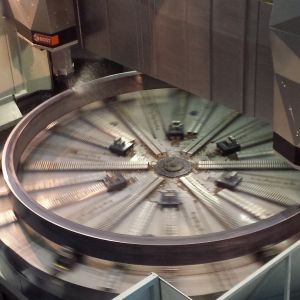

LATHING / BORING / MILLING

Diversity is our strength.

In accordance with customer wishes, all lathing, milling and boring operations are carried out on the most modern CNC lathes / vertical lathes and CNC machining centres.

Even 5-axis simultaneous milling operations present us with no problem. With help from the latest CAD and CAM technology, even the most complicated components can already be simulated in advance when it comes to production. In doing so, production risks and processing times are kept to a minimum.

The highest quality in every detail, even when using maximum sizes.

Some further main reasons for choosing processing with Kollmeder are: The calculable saving of time, the shorter lead time and the exclusion of the production risk for your company, as well as the considerable reduction of transportation costs through the elimination of intermediate transport and road toll costs thanks to delivery from one single source.

Processing – Everything from one single source.

Lathing:

- Swiss-type lathing: length 5.000 mm / diameter up to 1.100 mm / workpiece weight up to 6.000 kg

- Vertical lathing: up to 8.500 mm diameter / height max. 5.000 mm / workpiece weight up to 100 t

- both boring and milling operations can be carried out on all vertical lathing machines

Milling and boring:

- Moving column milling machines up to max. 16.000 mm x 3.500 mm x 2.000 mm

- Portal milling machines up to max. 6.000 mm x 3.000 mm x 3.000 mm

- Workpiece weight up to 40 t

Services

LAUNCH CAREER ROCKET!

TÜV-Certificates

ISO 14001 - DE (280.8 KiB)

ISO 14001 - EN (281.3 KiB)

AD 2000 W0 - DE (161.6 KiB)

AD 2000 W0 - EN (162.5 KiB)

10025 Zertifikat CE - DE (244.7 KiB)

10025 Zertifikat CE - EN (241.0 KiB)

Druckgeräterichtlinie 2014-68-EU_de gültig 31.10.2024_1.pdf (161.6 KiB)

Druckgeräterichtlinie 2014-68-EU_en gültig 31.10.2024_1.pdf (162.5 KiB)

ISO 9001 - DE (281.8 KiB)

ISO 9001 - EN (281.6 KiB)